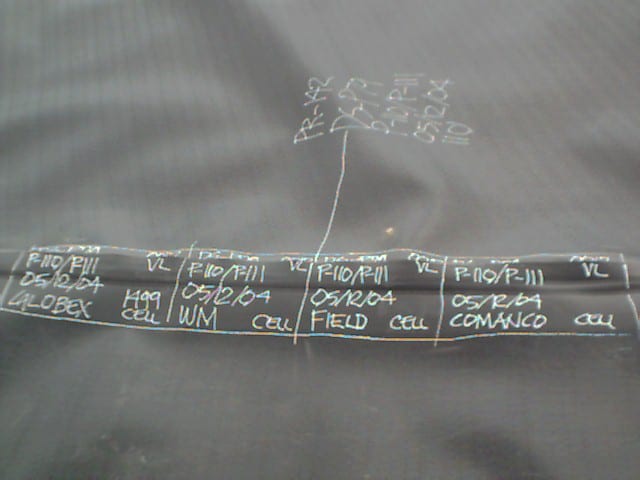

In destructive testing, tests are carried out to the specimen’s failure, in order to understand a specimen’s structural performance or material behavior under different loads. Liner installation requires a destructive test sample generally every 500 feet of a welded seam. It is tested by our field quality control technicians on COMANCO’s proprietary ‘5-station Tensiometer’ for peal and shear and then sent to an independent laboratory to be tested again.

COMANCO has reached a new milestone with a 99.5% pass rate for destructive tests, based on a test rate of 2,830 destructive samples, tested in 2015. This represents an improvement of 0.7 percent over 2014.

The accomplishment of this milestone is in direct relationship to COMANCO’s investment in IAGI training and certification for both wedge and extrusion welding technicians along with the dedication and commitment to quality improvement by every individual within COMANCO, from laborers to supervisors, and the quality control team.

Currently, 79 COMANCO liner technicians have received their certification and more certification testing is scheduled before the end of the year.

SAFETY ★ QUALITY ★ SERVICE