Back in 2009, COMANCO launched proprietary software for our geosynthetics installation services aiming to create an automated platform for all required QA/QC documentation.

COMANCO’s Computer Aided As-Built (CAAB™) program was developed with the intention of providing a more authentic and efficient means of documentation versus the industry norm of handwritten record keeping. Since then, CAAB™ has technologically advanced into something much more.

CAAB™ provides two essential functions: 1) authentic, automated documentation and 2) advanced search analytics.

Documentation:

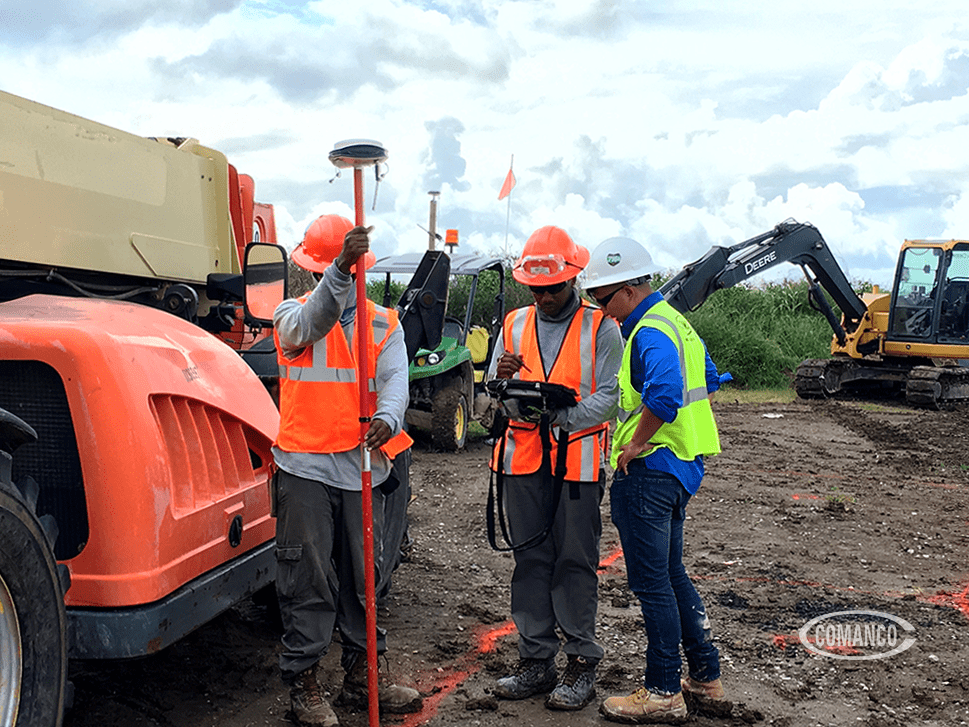

It’s in the name – ‘computer-aided as-built’. COMANCO is able to ‘tie into’ any one of its job sites via GPS satellite calibration, pinpoint all facets of the installed containment system (panel edges, repairs, penetrations, etc.) and assign GPS coordinates to each. From there, our CAAB™ program is coded to transform those GPS coordinates into three-dimensional as-built drawings inclusive of all pertinent features. Additionally, CAAB™ converts the shot GPS coordinates and their attached attributes to automatically populate seam and repair records – location, repair/seam number, seam length, date, time, etc. CAAB™ also provides integrated check systems that will not allow documentation to proceed without required predecessors. For example, users have the ability – or NONability – to document seams or repairs without corresponding trail seams on record for that particular welding technician and machine within project specific timeframe.

Analytics:

Which technicians have the lowest destruct failure rate? What equipment do they prefer? Which superintendent has the most square footage laid with least/most failed destructs? Which technician welded the most amount of different types of material successfully? What time of year do we do we perform our best or worst? What material do we need to improve on welding? Which technicians need additional training? Answering these questions is imperative to COMANCO’s continued growth.

With all information gathered for the documentation portion of the CAAB™, COMANCO saw an opportunity to collect all of that data into a centralized database and utilize it for internal auditing. We developed an advanced search feature that allows us to mix and match search metric options to better understand our proficiencies but also identify leading indicators to correct deficiencies before they get applied to a project.

Trial weld pass/fail rate, destruct pass/fail rate, LF welded broken down by extrusion vs. fusion, square footage deployed, repair type percentages, waste percentages and overall job tracking completion percentages. Then each of these can be broken down, even more, to be analyzed by a welder, machine, material, weather conditions, subgrade material, time of year, and more.

We use this information to improve our workforce and effectively staff specific projects to provide the best possible installs.

Continue to FOLLOW ‘COMANCO is QUALITY‘ on social media as we continue to share how Technology and qualified Personnel help us bring more value to our customers.

SAFETY ★ QUALITY ★ SERVICE