From the desk of Quality Control Manager Tammy Klish:

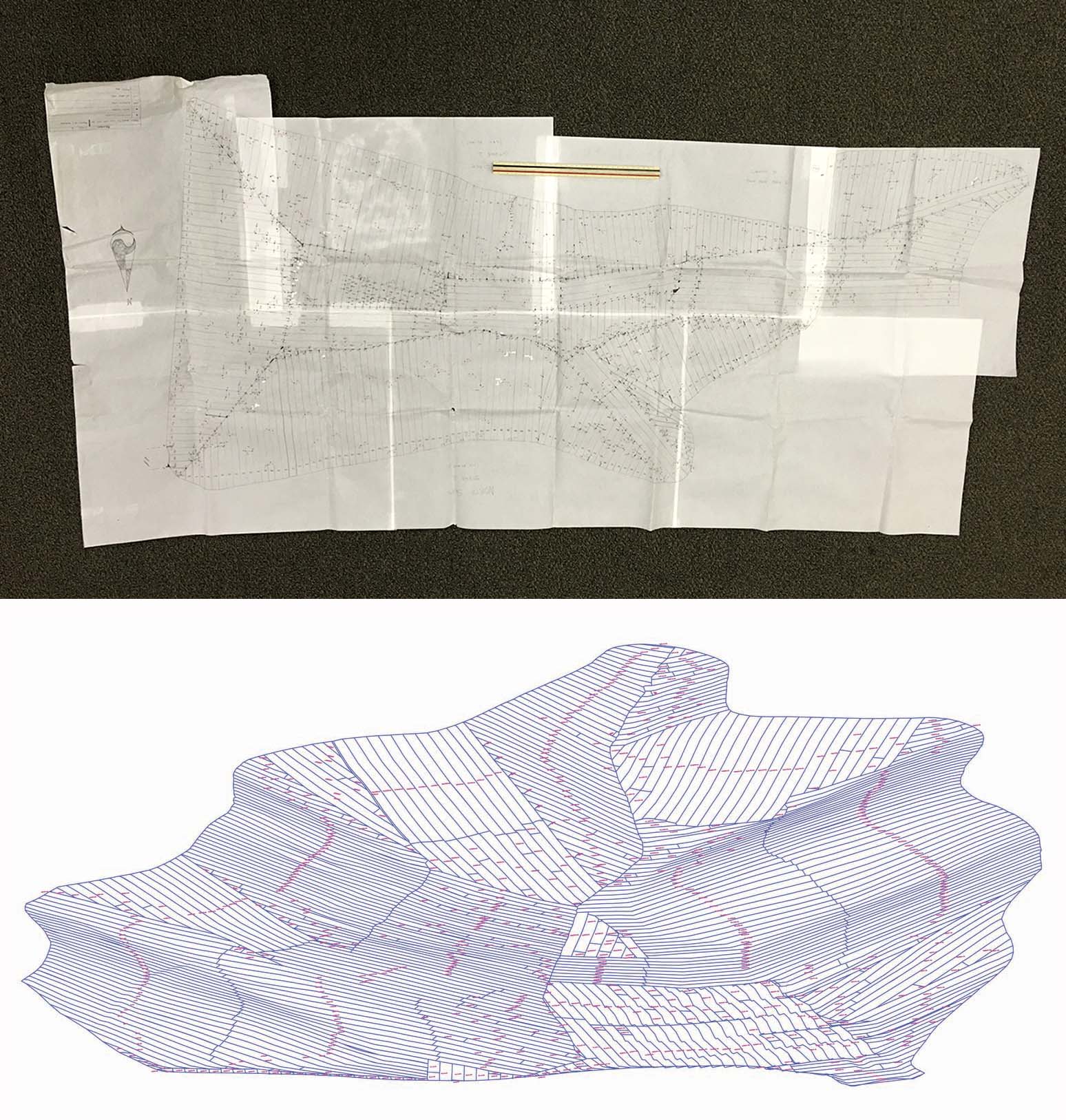

In today’s post, I want to take the readers on a journey into the not so distant COMANCO past, where as-builts were hand drawn, as are industry standards across the country when it comes to liner installation. Creating a hand-drawn as-built is an extremely time-consuming, labor-intensive process which results in a large, ponderous end product (as seen in the first photo). The technician has to use a measuring wheel to measure every seam. The location of every repair and destruct has to be measured and documented on the bottom (and sometimes side) of the panel to the point of the repair.

Quality is a continuously evolving process. At COMANCO, we are not satisfied with industry standards.

Today at COMANCO, as-builts are created using a combination of GPS survey and our proprietary software, CAAB. The survey system increases seam location and repair accuracy and decreases the amount of time needed to document seams, repairs and destructs and reduces the chance of human error. It is far less strenuous than using the measuring wheel. With the CAAB software, as-builts are created in a 3D view of the project (as seen in the second photo), providing engineers and clients a QUALITY end product that is unsurpassed in today’s market.

And this is just the beginning. At COMANCO, we are continuously exploring innovative technology to improve our quality and remain the industry leader in liner installation.

SAFETY ★ QUALITY ★ SERVICE