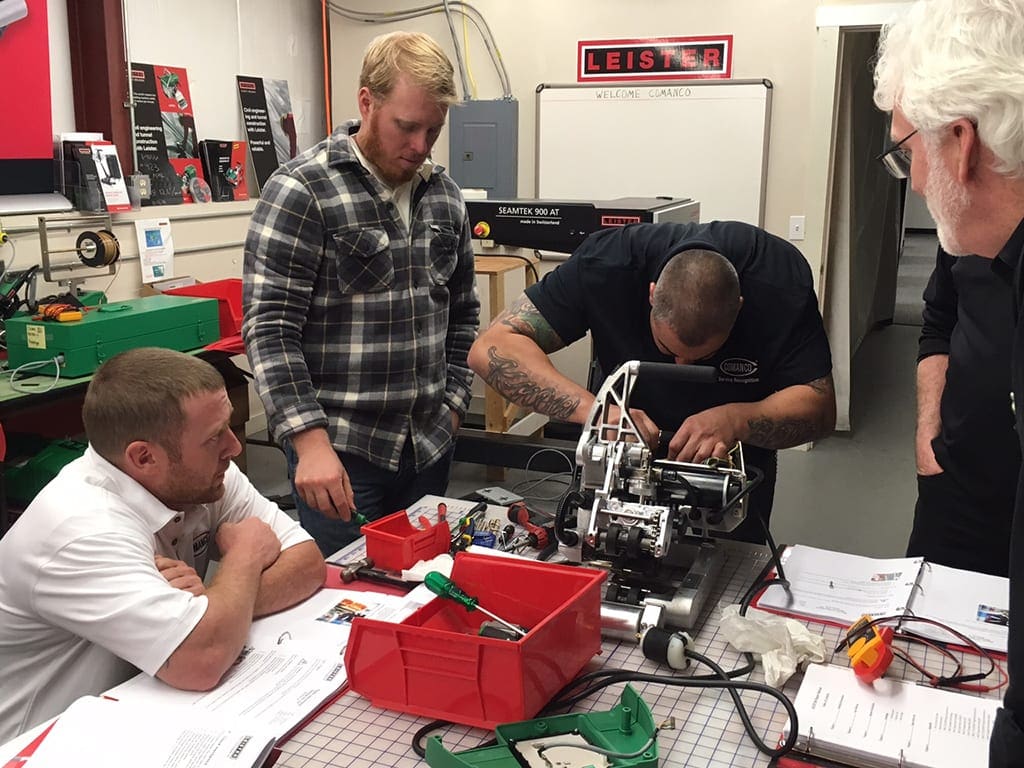

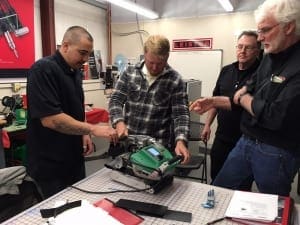

On April 6th, Fleet Supervisor Tony Cole, Liner Equipment Technician Justin Grenke, and Equipment Technicians Sam Smith and Michael Pavlik attended a training class at Leister’s facility in Tiverton, Rhode Island. The training primarily covered the new Geostar G7 Wedge Welder. With our recent acquisition, we currently have 12 of these units in our fleet. The training covered many aspects of these units including safety, tear-down, repair, service, and setup. This removed much of the apprehensions we all had regarding this equipment that is new to COMANCO. The staff at Leister did an outstanding job hosting as this exceeded all of our expectations. This is what our employees told Supervisor Tony Cole about the training experience.

Justin stated, “The Training Leister provided us with on the new Geostar wedges was well worth it & very in depth, supplying all of us w/ great new service & USB manuals for the new equipment, which will be very helpful. Thanks go out to Steve Hobbs & everyone on the Leister team we had the pleasure of meeting.”

Mike stated, “Upon arrival at Leister, I had never serviced any welding or hot air equipment, so I felt like it was another world to me. Only 2 to 3 hours into the training I felt comfortable with the equipment and confident in my ability to maintain and service the equipment. In total, I personally took away a great deal of information and established connections with the Leister team in Rhode Island.”

Sam stated, “This was a great experience for me. After 8 years of working with liner, sending equipment out and calling Mr. Hobbs for help, I finally got to meet the pro’s in person and see the shop they work in. As for the G7, I feel more confident in taking out control boards and taking the block apart. Also, the pointers on grease and the Moly-kote for the heat cartridges will be very useful. Just seeing those guys and how they operate, like setups and tests, knowing they have got way more experience than me was a good eye opener. I learned I need a few more tools to make life easier. I also learned a lot about Leister and what else they do regarding other products and materials they work with. They explained everything to us. Also, the little technical things that I never realized before was very interesting and very good to know. “

SAFETY ★ QUALITY ★ SERVICE