Spotting Liner Defects – A Guide to Maintaining Your Liner and Preventing Major Issues

Geosynthetic liners are essential to many industrial, agricultural, and environmental projects. They provide a reliable barrier against leaks and pollution, making them popular in various applications. However, like any other material, liners can wear down over time, leading to defects that compromise their performance. Knowing when to call your installer for geosynthetic liner repairs can be challenging, especially if you need to familiarize yourself with the signs of liner failure. That’s why we’ve created this guide, emphasizing the importance of early detection, empowering you to take proactive steps to maintain your liner and prevent costly repairs.

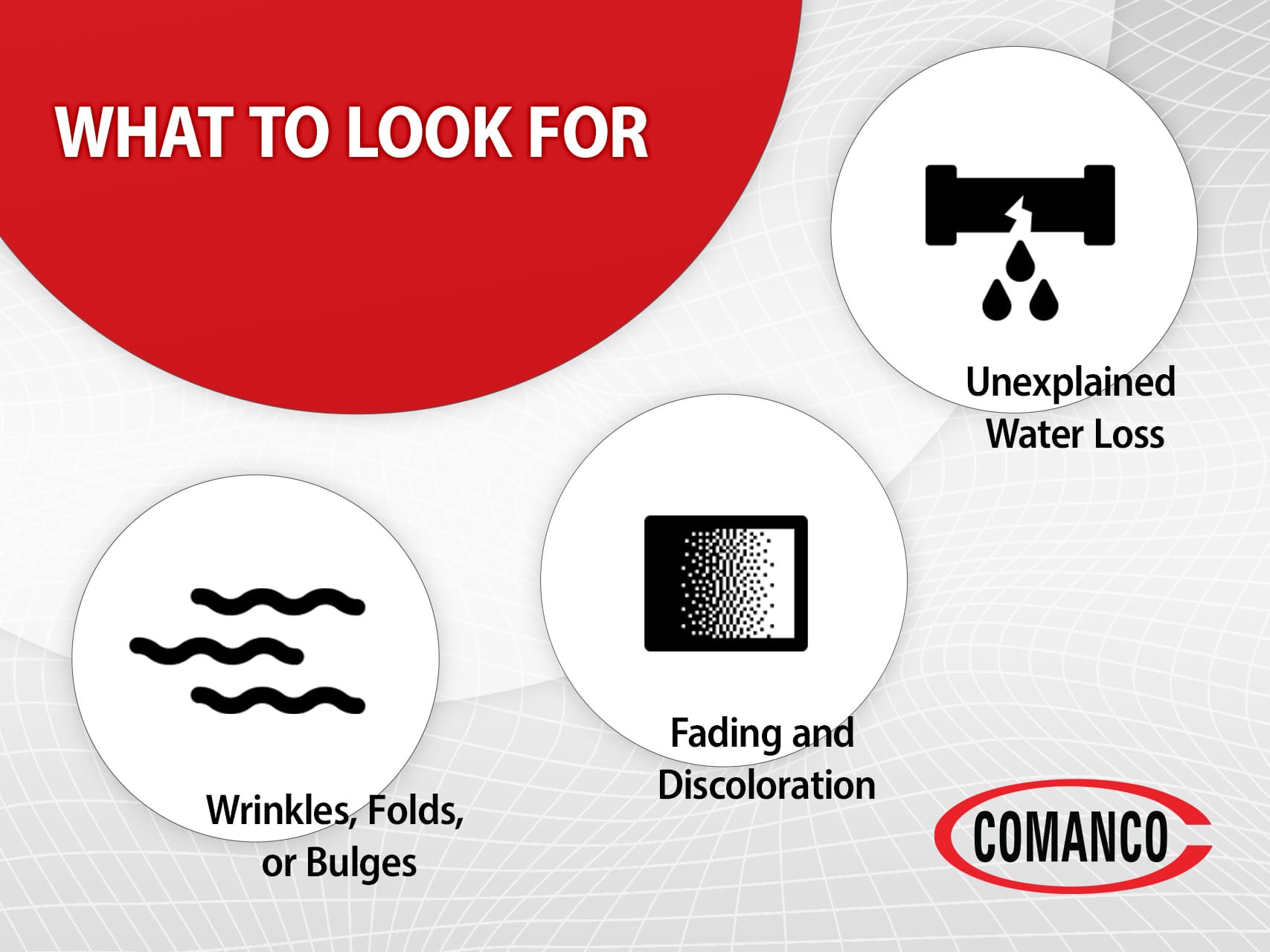

What to look for:

The following are some of the most common signs of geosynthetic liner defects:

- Fading and discoloration: Liners exposed to significant UV exposure tend to fade and discolor over time. Fading and discoloration can indicate a loss of strength and flexibility, making them more susceptible to punctures and tears.

- Wrinkles, folds, or bulges: Liners that are not installed correctly or have shifted over time can develop wrinkles, folds, or bulges. These deformities can create stress points that weaken the liner and increase the risk of leaks.

- Unexplained water loss: If you notice a sudden drop in water levels in your containment system without any apparent cause, it could be due to a leak in your liner. Water loss can be a severe issue, as leaks can contaminate soil, water, and air, leading to environmental and financial damages.

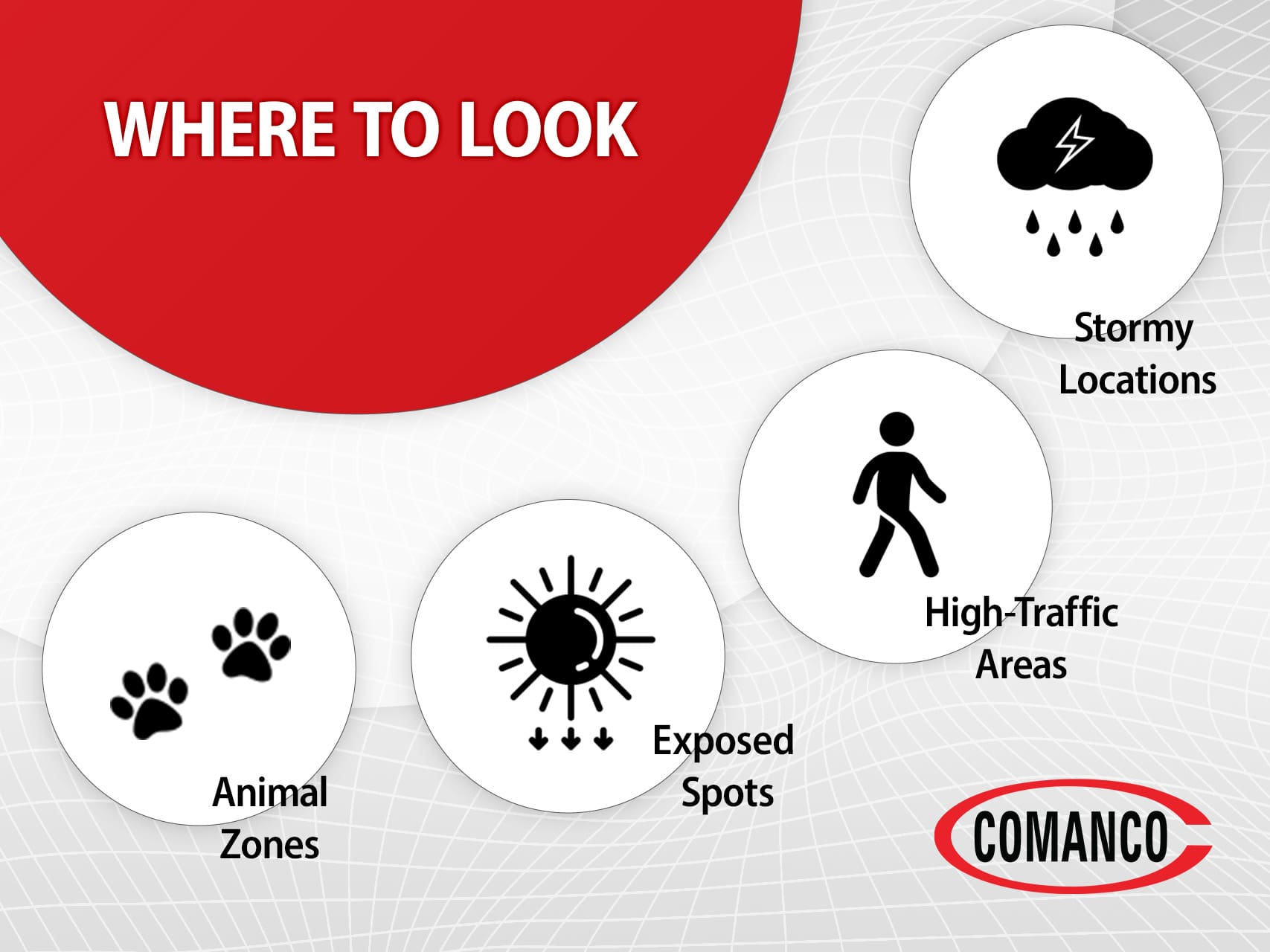

Where to Look:

Certain areas and conditions can make liners more prone to defects:

- High-traffic areas: Areas that experience frequent foot or vehicle traffic are subject to damage due to abrasion, puncture, or tearing.

- Animal zones: There is a higher risk of liner damage when wildlife is near your project. Animals can scratch, bite, and tear liner, leaving it susceptible to leaks.

- Exposed spots: Liners exposed to extreme weather conditions, such as high winds, heavy rain, or extreme temperatures, can deteriorate faster than those protected undercover.

- Weather conditions: After a storm, inspect your liner for any visible damage caused by wind, debris, or flooding.

Other Tips and Tricks:

By following these tips and tricks, you can maximize the lifespan and effectiveness of your geosynthetic systems:

- Be Proactive: Take the time to schedule inspections ahead of time before issues arise. Always keep your eye out for signs of wear and tear.

- Don’t Procrastinate: Liner repairs should be prioritized. Procrastinating liner repairs can cause minor issues to become big headaches quickly.

- Never Cut Corners: When it comes to repairs, it’s safer and more cost-effective to get it done correctly the first time. Temporary or mediocre fixes will only prolong the problems.

COMANCO: Your Liner Repair Specialist:

Our team of expert liner repair technicians offers timely and efficient liner repair services. We work with clients to create a custom repair plan that meets their needs quickly, especially in emergency repairs. Our experienced technicians can diagnose the problem, recommend the best course of action, and get your liner back in top shape quickly and efficiently. Contact us today for a free quote on your repairs or to schedule an inspection and beat the issues before they arrive.

In conclusion, geosynthetic liners are an investment in the long-term success of your project. By being vigilant and proactive in maintaining your liner, you can prevent significant issues, reduce costs, and ensure the environment’s and people’s safety.

SAFETY ★ QUALITY ★ SERVICE

COMANCO is a leading environmental, commercial, and civil construction company specializing in constructing containment facilities.

Are you interested in COMANCO’s worldwide impact? Our Geosynthetic installations aid a wide variety of industries worldwide. Explore our services to see how we can help your industry achieve sustainable outcomes.

4301 Sterling Commerce Dr, Plant City, FL 33566

(813) 988-8829 | www.comanco.com